TRENDS COME AND GO, QUALITY REMAINS.

The PIEPER GmbH is a manufacturer-independent provider of industrial video and security systems and process monitoring. Expertise, experience and efficiency are the PIEPER GmbH - then as now.

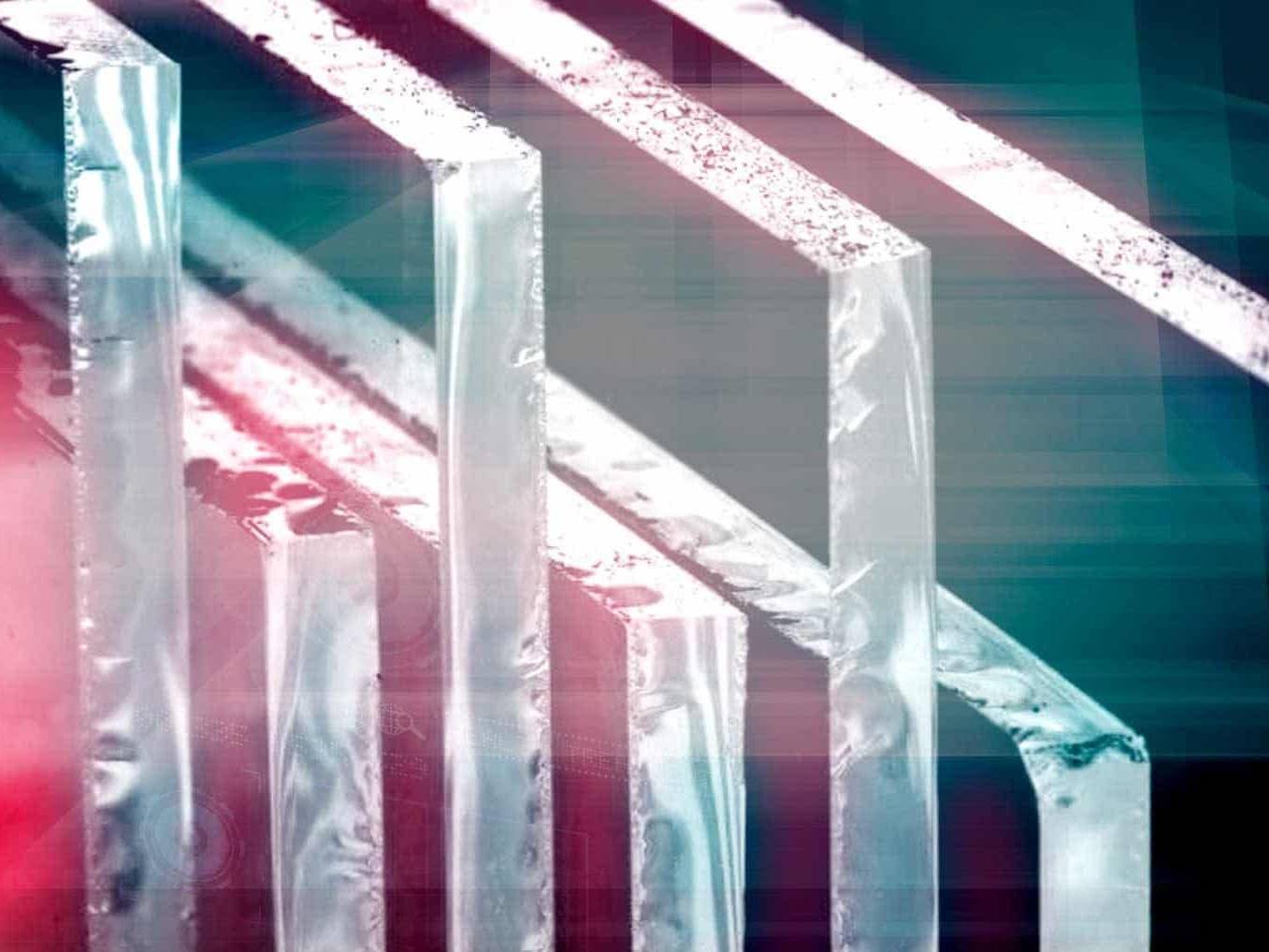

Individual process monitoring and state-of-the-art thermovision for your company!

Process monitoring for more safety and effectiveness. For more than 50 years, your safety has been in good hands with the PIEPER GmbH has been in good hands. With our headquarters in Schwerte and four further branches, we are represented throughout Germany in the field of thermovision and visual process monitoring. With the help of our international partners, we plan, develop, manufacture and install complete video, image processing and security systems for industry - independent of location and worldwide.

Our experienced experts work together with a long-standing, reliable and international partner network so that your requirements for perfect process monitoring are optimally met at all times. From planning to implementation to maintenance of your individual safety systems and solutions, we are at your side at every point.

Latest News

1 February 2022

Optical process monitoring in industry

Industry with a future:Significant competitive advantages thanks to optical process monitoringModernisation in the...

9 August 2021

Radial MP lens for precise monitoring of furnaces

PIEPER introduces a specially designed component for modern process monitoring in industrial environments:...

26 November 2020

Thermal imaging camera system for contactless temperature measurement

Another system for contactless temperature monitoring of people is now available from the Schwerter...

Individuality

With many years of experience, excellent market knowledge and technical expertise, we design security solutions and guarantee accurate process monitoring. In doing so, we always respond to the individual needs of our customers.

Complete support

At all times, the customer is the focus: from consulting and project planning, through installation and commissioning, to extensive after-sales support.

Service

Quality is our top priority. In addition to our solutions, this also applies to our support. Regular training of our certified trainers will make you fit for Industry 4.0.

International presence

We transcend borders and are well connected. Through worldwide partnerships and cooperations, we also ensure constant availability internationally. We always meet all individual requirements.

Industry solutions - individual process monitoring

Process monitoring - Our focus

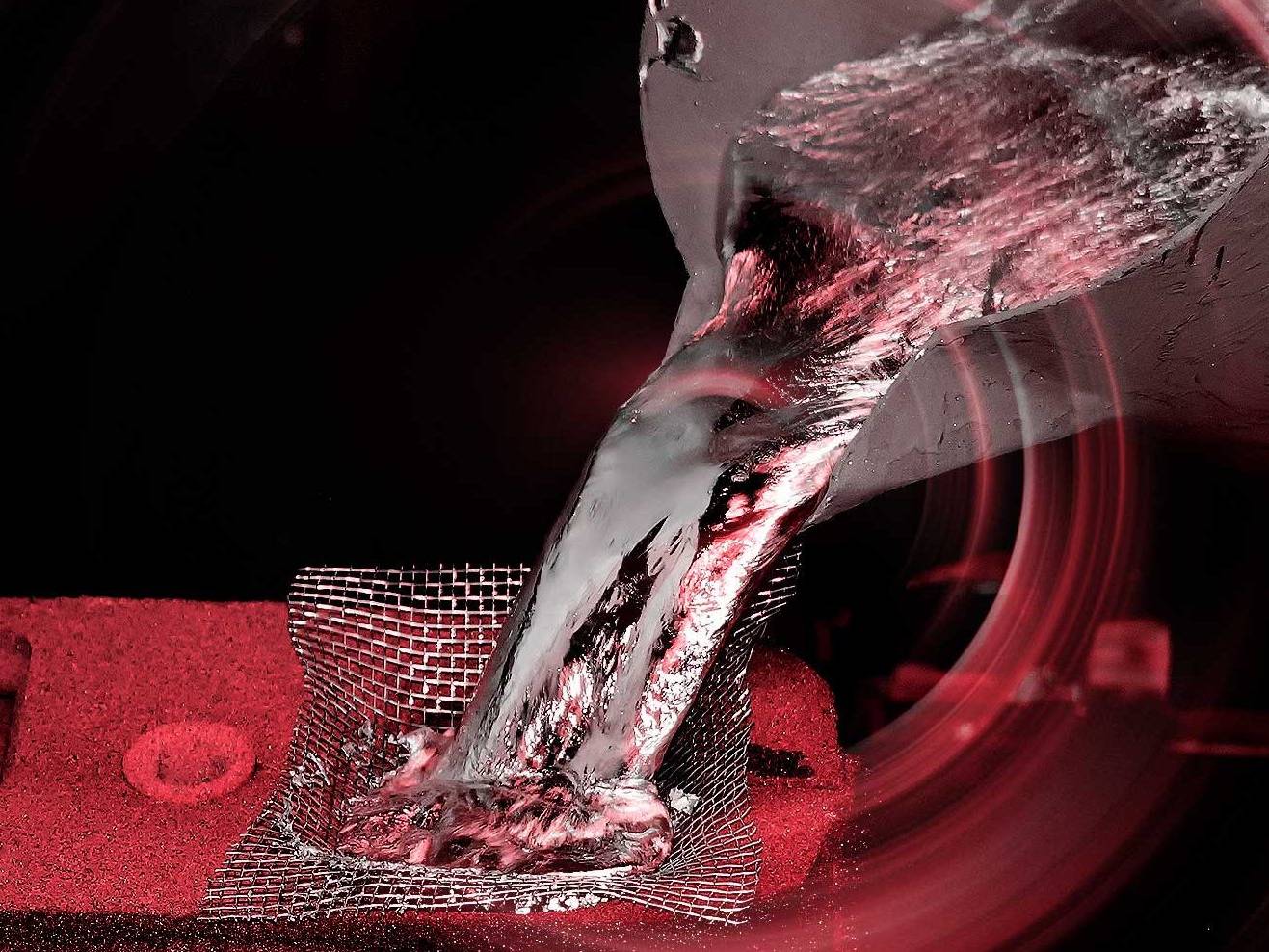

The focus of the owner-managed company is on industrial hot and combustion chamber monitoring as well as visual process monitoring and production control. Furthermore, we design systems for early smoke and fire detection and IP-based individual security systems for plant and site protection.

WITH US YOU ARE ON THE SAFE SIDE – TODAY AND IN THE FUTURE!

System solutions and thermovisionfor every industry

Customers have been appreciating our manufacturer-independent consulting, our industry-specific know-how and high-quality special solutions in:

Contact us